Drivers

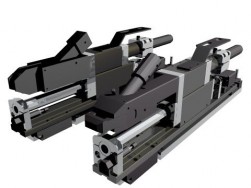

Most applications can be handled using our standard Building Block system, which allows configuration flexibility through use of cost effective standard components. A wide variety of air or electric drive motors with or without torque monitoring can be mounted on standard drive spindles, making it easy to select the proper motor for each application.

The standard receiver (nose) bodies, mount blocks, etc. are machined from 6061 T6 aluminum. Drive spindle cylinders, slide cylinders and slide base rails are extruded from aluminum. All surfaces subject to rubbing wear or contacted by seals are heat treated with a hard-anodized finish to reduce wear and friction. Extensive use of aluminum is an advantage in applications where overall driver weight must be kept to a minimum. The screw path consists of hardened steel inserts that allow rapid replacement at a reduced cost. The insert system permits rapid conversion to other size applications by changing the low-cost fastener path inserts. Jaw pockets are standard in each receiver body size permitting easy jaw size changes when necessary.

A drive unit mounted on a Deane Systems standard primary slide assembly becomes a self contained drive system that can be operated at any angle and is self-clearing when cycled in the proper sequence. The self-clearing function is absolutely necessary when the application is automatic and unattended.

Standard primary slides are equipped with shock absorbers to allow rapid cycling with smooth stops at each end of the stroke. Slides are also equipped with a proximity switch actuator to indicate slide position. Brackets for 12mm threaded barrel proximity switches are provided for customer supplied switches. Deane Systems will quote switches upon request.

We look forward to assisting you with your fastener feeding and drive applications.

The standard receiver (nose) bodies, mount blocks, etc. are machined from 6061 T6 aluminum. Drive spindle cylinders, slide cylinders and slide base rails are extruded from aluminum. All surfaces subject to rubbing wear or contacted by seals are heat treated with a hard-anodized finish to reduce wear and friction. Extensive use of aluminum is an advantage in applications where overall driver weight must be kept to a minimum. The screw path consists of hardened steel inserts that allow rapid replacement at a reduced cost. The insert system permits rapid conversion to other size applications by changing the low-cost fastener path inserts. Jaw pockets are standard in each receiver body size permitting easy jaw size changes when necessary.

A drive unit mounted on a Deane Systems standard primary slide assembly becomes a self contained drive system that can be operated at any angle and is self-clearing when cycled in the proper sequence. The self-clearing function is absolutely necessary when the application is automatic and unattended.

Standard primary slides are equipped with shock absorbers to allow rapid cycling with smooth stops at each end of the stroke. Slides are also equipped with a proximity switch actuator to indicate slide position. Brackets for 12mm threaded barrel proximity switches are provided for customer supplied switches. Deane Systems will quote switches upon request.

We look forward to assisting you with your fastener feeding and drive applications.