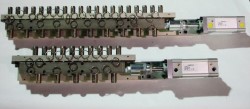

Diverters

Our air piloted and linear rail diverters allow a single escapement to deliver parts to two drivers or placing units or nest fixture.

Multiple diverters can be used in tandem, adding one delivery point per diverter used for each connected escapement. Diverters can be a cost effective alternative to additional feeders which saves floor space, controls and less maintenance. We have diverted screws, bolts, nuts, clips, cup plugs, pipe plugs, dowels for many customers thus saving them extra capital equipment costs.

Our air piloted diverters use hard-coated 6061 aluminum cylinders with a Teflon impregnation to shift the diverter.

Hardened steel entrance and exit sleeves provide an extremely durable part path. All steel components are electro-less nickel plated for added corrosion protection and wear resistance. Tubing adapters with tubing retention screws securely anchor the blow feed tubing into the sleeves.

Flow controls for each piston are easily accessed for minor adjustments if necessary.

The entrance and exit sleeves can be changed out to accommodate different size fasteners thus reducing the cost of additional units and creating a greater flexibility to your equipment.

Linear FTD – Feed Tube Diverters use standard off the shelf THK or Nook rails and carriages as well as standard air cylinders such as Numatics, SMC, PHD, or Bimba. They also come standard with quick release pins for quick removal of sleeves during maintenance operations.

Diverters whether the air piloted or Linear can also be used to divert rejected components to bins or a designated location. Several of our projects used diverters to reject wrong length bolts that had been accidentally put into the feeder. These sent the fasteners to a bin attached to the side of the feeder which was checked each shift.